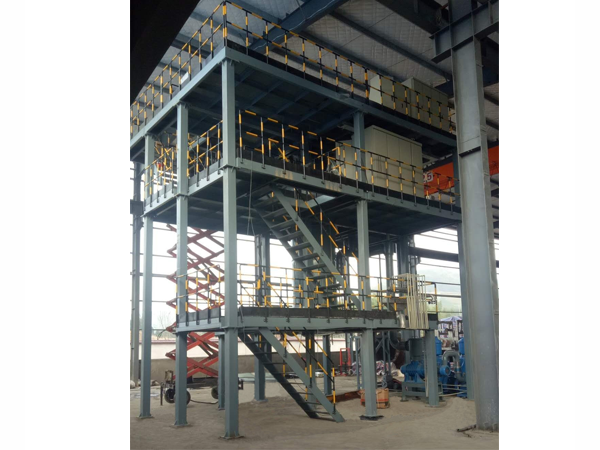

Vacuum induction atomizing furnace is utilized to produce metal powder by using gas atomizing technology.

The metal melted by using induction heating technology firstly, then the melted metal be atomized through highly pressurized inert gas , after condensation, the fine particles(powder) will be formed.

We can produce metal powder of different diameters by adjusting the pressure and velocity of inert gas.

The furnace made for producing metal power of high purity and low ppm(oxygen content), it can also utilized to produce metal powder of any compositions and complex material.

It is widely used in 3D printing,navigation, aerospace, national defence, scientific research and other related industries.

Main technical parameter

Model | ZGF-25 | ZGF-50 | ZGF-100 | ZGF-200 |

Rating capacity(Kg) | 25 | 50 | 100 | 200 |

Rating power

(Kw) | 100 | 100 | 160 | 300 |

Working temp(℃) | 1800 | 1800 | 1800 | 1800 |

Final vacuum

(Pa) | 6×10-2 | 6×10-2 | 6×10-2 | 6×10-2 |

Pressure rise rate(Pa/h) | 3 | 3 | 3 | 3 |

Temperature

sustaining(℃) | 200-1100 | 200-1100 | 200-1100 | 200-1100 |

Nozzle pressure(MPa) | 5-15 | 5-15 | 5-15 | 5-15 |

Mid-frequency

power supply

voltage(V) | >200-250 | 200-250 | 200-250 | 200-250 |

Frequency(HZ) | 2500 | 2500 | 2500 | 2500 |

Note:Above is VIGA furnace(with crucible) ,we can also provide EIGA(no crucible furnace) and production technology.